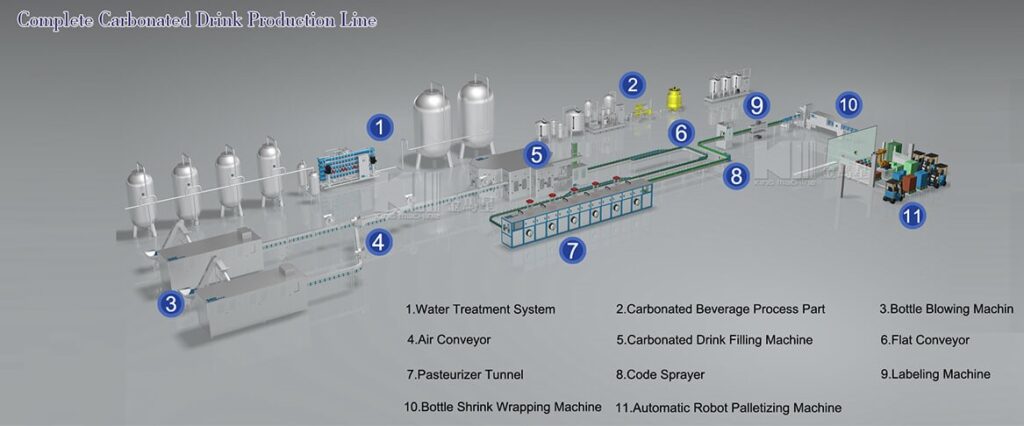

Carbonated Beverage Production Factory

A CSD Factory is a complete, state-of-the-art facility designed for the production of carbonated soft drinks, combining precision engineering, automation, and hygiene standards to ensure consistent product quality. The factory integrates all key processes — from water treatment, syrup preparation, and CO₂ mixing to bottle blowing, filling, labeling, packaging, and palletizing — creating a seamless production flow.

Each system is optimized for efficiency, accuracy, and flexibility, allowing production of multiple SKUs such as 250ml, 500ml, 1L, and 1.5L PET bottles. With advanced control systems, energy-efficient equipment, and automatic quality monitoring, the CSD factory ensures smooth operation, high output, and excellent taste consistency.

Water treatment system

- Features: Treatment capacity 0.5-50T/Hr. with customized deign option asper requirement.

- Remove 99.9% ions, adopted Hydecnme (American brand) membrane, body material SS304 & SS316. Fully automatic control and water testing system

- Equipment including are pre filtration, hollow fiber, RO, UV sterilizer, precision filter, ozone generator, water tank etc.

Pre Filtration

Silica sand filter/active carbon filter/sodium ion exchanger, these pre filters remove different kinds of foreign particles (i.e. suspended particles, heavy metals, sulphides, hydrogenate, Na++, Ca++, Mg++ etc.) to clean feeding water and protect following machines .

- Capacity range- 3T/Hr – 70T/Hr

- Material – all tanks & pipes SS304

- Automation- HMI controlled recipe system (optional)

Micro filter

Multiple 3mm thick, PP membrane used to remove fine particles up to size of 1-5 microns. It improve performance of life of RO membrane.

RO System

The device’s key part is reverse osmosis membranes that is from the America, it has a good performance to eliminate salts with high-pressure pump. Main features as below.

- Removes up to 90–99% of total dissolved solids (TDS), salts, and other impurities.

- Optimized for 50–75% recovery, depending on feed water quality and system design.

- Can be design in single or multiple membrane housings (pressure vessels) to match the plant’s capacity requirements.

- Plug-and-play design allows quick membrane replacement and minimal downtime.

Post treatment

UV sterilizing system

- The products adopt a high-intensity, long-lived UV germicidal lamp to achieves up to 99.99% microbial kill rate, ensuring water safety at the final stage.

Ozone mixing system

- Ozone (O₃) effectively destroys bacteria, viruses, mold, and organic contaminants improving clarity and taste.

- Decomposes naturally into oxygen after treatment — no harmful byproducts.

Product tank

- Designed to store RO-treated or sterilized water before distribution or filling, ensuring maintained purity and quality.

- Made from food-grade stainless steel (SS304/SS316) to prevent contamination and corrosion. Made from food-grade stainless steel (SS304/SS316) to prevent contamination and corrosion.

Processing System

The Processing System is the heart of the CSD production line — where raw materials such as treated water, sugar, flavors, and carbon dioxide transformed into a finished beverage ready for filling. This stage determines the taste, consistency, carbonation quality, and shelf life of the final drink, making it one of the most critical areas of beverage manufacturing.

Our processing system integrates several interconnected units working in harmony to ensure precise mixing, accurate carbonation, and hygienic handling of the beverage. All equipment (like tanks, filters, piping, valves, pumps, heat exchangers, etc.) are food grade made of SS304/SS316 and process flow is design as per GMP standards with advanced automation.

Hot water tank

Hot water used for sugar melting and CIP system. Here treated water heated by steam through plate type heat exchanger and supply to plant as per requirement. Tank features are real time temperature & flow checking and control with pneumatic valves. SUS304 double layer tank, PU insulation, insulation thickness 50mm, inner liner 3mm, outer 2mm. Conical head, top closed manhole and ladder, top water inlet and return port, with overflow pipe, float ball high, medium and low level, sign and digital thermometer, glass tube level gauge, bottom pull rod valve outlet, with temperature sensor interface, adjustable foot.

Sugar melting/mixing tank

High speed emulsifying tanks used for mixing sugar in hot water. Multiple advance features made this equipment most advanced like bottom emulsifier with 1450rpm, highly accurate temperature sensors, capacitive high and low level probe interface, automatic weighing system, double barrel filter, two stage plate heat exchanger, etc.

Tank with top closed manhole, top water inlet and CIP spray ball, vent cap, strong pumps and adjustable foot is easy to use and maintain.

Ingredient mixing tank

Features: made of SS304, round, semi-open, double layer, PU insulation, inner liner 3mm, outer 2mm, top shear head, speed 1450rpm, top shear head, speed 2900rpm, top closed manhole, top water inlet and CIP spray ball, ventilation cap, label and digital thermometer, capacitive high and low level probe interface, static pressure sensor, double barrel filter, pneumatic valves, proximity sensor and adjustable foot

Batch mixing tanks

Features: SUS304, half layer, plate thickness 3mm, conical head. 4-block Weighing module. Offset vertical mixing at the top, speed 0~46rpm, with acid nozzle at the top. Top center CIP spray ball, vent cap side feed, glass tube level gauge, sampling valve, closed manhole. Label and digital thermometer, bottom pull rod valve, anti-vortex plate. Centrifugal pumps, double barrel filter, three adjustable feet.

Batch filter system

SUS304, with 100/150/200M nylon filter as per application. It is equipped with four manual disc valves for switching, with a small exhaust ball valve on the top and a small blowdown ball valve on the bottom

CIP system

Automatic CIP system is specially designed for the clean up of beverage production line and filling equipment, with three cleaning sections of Acid, Alkali and Hot water and temperature can be set up as per requirement.

Function: The CIP SYSTEM can cleaning equipment of blending system automatically, from start until to the end of cleaning Work, all jobs are done by the control system automatic performance which function had been set in advance, the operator only Makes the switching operation, all blending system equipment will be cleaned fast and simply.

Features: SUS304, split type, double circuit design, four tank system, tube heating, automatic control, acid, lye, hot water tank are thermal insulation tank, single-layer clear water tank, inner cylinder 3mm thick, outer 2mm thick, insulation tank using PU polyurethane foam, thickness of 60mm. The top of the acid and lye tank is offset and stirred at 36rpm.

In full automatic system can control product in and out, heating temperature and discharge temperature, automatic control and compensation of acid and alkali concentration. Automatic adjustment of cleaning flow, automatic alarm of cleaning equipment failure, automatic control of tank liquid level, automatic switching of CIP process

PET Blowing section

Linear type full electric(energy saving with variable pitch) PET bottle blow molding machine is a high speed automatic PET blower designed and developed with the most advanced bottle blowing technology at present.

Working: The perform transfer system with grippers and the variable pitch system are both driven by the servomotors to ensure high speed and accurate preform handling between the two mechanism. The Servo driven molding mechanism, triggering off the linkage to the bottom mold. The cooling system for the preform neck is equipped to ensure the preform neck does not deform during heating and blowing. The high pressure blowing system is equipped with the air-recycling device, which may reduce the air consumption to achieve the energy-efficient and environmental safe. Being highly intelligent, the machine is equipped with the units of preform temperature detection, leaking bottle detection and rejection as well as jammed air conveyor detection, etc. which ensures the machine work efficiently and stably. Operation on the touch screen is simple and easy

Features: Machine with from 2 to 10 cavities can achieve 4,000 to 20,000 b/hour on 0.55 liters with water bottles. It is mainly applicable in blow molding PET containers for water, beverage, juice, etc.

Advantages can described as speedy, stable, simple, general purposed and environmental safe. Equipped with preform auto loading system, the machine works fully automatically with consistent performance and high speed, without any operator’s interference during the whole processes. Accordingly, chance of contamination can reduced manifestly, which assures the quality of products.

Our rotary blowing machine is specially designed for CSD bottles production. With various models (like 10cavity, 16cavity, 20cavity) can achieve 15,000 to 36,000bph output. The average energy consumption of 50 ~ 200kw/h (not including the auxiliary power output).

Working: Preforms are first loaded and evenly heated in an infrared oven, then transferred to the blowing wheel where high-pressure air and mechanical stretching form the bottle shape. The bottles are then cooled, ejected, and conveyed via an air conveyor system directly to the filling line, ensuring smooth, hygienic, and efficient production for CSD packaging.

Features: Our rotary bottle-blowing machine using vibration type preform hopper with elevator type transferring, Innovative heating and blowing technology. In the bottle blowing to achieve unparalleled efficiency and quality, while ensuring lower bottle blowing costs. Suitable for various volume (0.6 to 1.5 liters) and package type (PET).

Filling system

As a leading liquid filling machine supplier, F&N provides high-quality products for soft drink manufacturers. We offer a wide range of automatic CSD filling machines in different capacity-2000 – 36000bph to meet your needs.

In past 2 decades, we developed our technology from separate machines to mono block and now combi block-the most advance and stable in the world.

Carbonated drink 3-in-1 filling machine is also well suited for your production line. The three functions of bottle rinsing, filling and capping are compose in one body of the machine. The whole process is automatic. The machine is use in filling carbonated beverage and carbonated water in PET bottles. The handling/changeover of the machine convenient for filling of various types of bottles. The filling operation is faster and more stable because the micro pressure filling operation of the new type is adopt. Therefore, the output and benefit of the machine is higher than the machines of the same specifications. The machine is an idea-preferred equipment for beverage makers

Combi-block filling machine, also called blowing filling capping combi-block. Specially designed for précised/accurate product at high-speed like12000bph-54000bph.

The main advantages of the combi-block are high efficiency with better quality product, large output, less space, less operator, saving resources and costs with higher earning. Attractive Features are below

- Mechanical or volumetric electronic filling valve

- Tubular type filling bowl no dead angle, easy to clean

- Automatic CIP, easy for operation and maintenance

- Raise filling temperature above 12~15°C for energy saving

- Volumetric valve leads to high filling precision, 5~6 times higher than mechanical valve

Volumetric valve filling can realize fast changeover, no vent tubes

Gravity type mechanical valves |

Semi auto pneumatic valves

Full auto electric valves (volumetric)

|

CO2 Mixer

QHS series drink mixer is design and made for improving the proportion of water, syrup and carbon dioxide. It adopts foreign advanced technology—static mixer to lighten water layer, increased carbonizing time, assure mixing result and deoxying. It adopts high-quality water pump and SEIMENS electrical equipment and other parts to form complete automatic control system. It has coordinating action, beautiful appearance, convenient washing, high automatic level and other advantages. It is suitable for mixing all kinds of drink, such as soda water, fruit juice, Cola and other soft and hard drink. Large area of gasquid mass transfer, small resistance loss, high efficiency, low energy consumption, and simple structure. It also adopts the multi-stage centrifugal pump with reliable performance and low noise, guaranteeing the performance of the whole machine

The Volumetric CO₂ Mixer is based on advanced technology that analyze final product on real time with the help of latest sensors and controllers to control product quality precisely and accurately. Machine is designed to accurately blend treated water, syrup, and carbon dioxide in precise proportions. It uses volumetric dosing technology to ensure consistent product quality and carbonation levels. The system deaerates water, cools it to the ideal temperature, and injects CO₂ under controlled pressure, creating a uniform and stable carbonation effect. Its PLC-based control, automatic ratio adjustment, and stainless-steel hygienic design make it ideal for high-speed beverage production, ensuring a refreshing taste and consistent quality across all SKUs.

Warming tunnel

After the filling machine, there must be a bottle warmer to heat the bottle to the room temperature. The warmer is usually a tunnel type shower. It heats the bottle through spraying hot water to the bottle. There are usually 3 warming zones (more zones are ok). After heated by section, the bottle’s temperature could achieve 30-35 ℃. Main components of bottle warmer are frame, transferring chain, transferring system, water storage tank, recycle pump, showering device, heating device and pipes.

- Capacity :250ml cans :30000 cans/h

- Total treatment time :45minutes

- Applicable can size : diameter 50-110, height :H300mm

- Effective treatment area:36m2

- Electricity power consumption :25kW /among this : main motor 0.75kw

- Consumption: Water consumption:2.5t, Steam consumption:1500kg

- L*W*H=18000*3700*1670mm + 8000*3700*1670mm

- WORKIGN HEIGHT :H=1250mm / Weight:8 ton

Air dryer

This machine installed after the filling machine/warming tunnel, In order to dry the bottles body from outside. This machine is used to removing the water outside the bottle surface;

the major component of the machine is air blower. With the help of high-speed motor, it through the air on bottles and remove water drops from it. The blowing capacity can be adjust through the button.

Labeling system

The OPP Labeling Machine is designed for high-speed and precise labeling of PET bottles using Oriented Polypropylene (OPP) labels. It ensures smooth and accurate label application with minimal material waste, making it ideal for beverage, water, and food production lines. Featuring automatic label positioning, hot-melt glue system, and PLC control, the machine delivers consistent performance even at high speeds. Its stainless-steel structure, energy-efficient design, and easy maintenance make it a reliable choice for modern packaging operations.

Features:

- Adopting four pole support method,

- Adopting the latest straight in and straight out adhesive coating method.

- Adopting the latest adjustable collision block structure.

- Adopting multiple servo motors for accurate motion of mechanical parts

- Adopting an independent module approach for heating system.

- Adopting the German imported Leimer E+L label correction system.

- The machine is equipped with dual material tray with automatic label connection system.

In order to meet the needs of markets at home and abroad, our company has researched and developed double head mechanism to meet the requirements of casting label for casting label for bottle mouth and bottle body. Automatic Double Heads Sleeve Labeling Machine.

- The shrinkable film roll with adjustable locking gear, can be adjusted according to different roll 5-10

- The applicable bottle is the machine square bottle and round bottle

- Without tools, the driven machinery can be adjusted to meet different bottle size

- Particular inserting label ways i.e. inserting label, it is reasonable and convenient.

- Full automatic feeder, the flat shrinking and tension are adjusted together.

- It is assured to low error that there is inspection of rolling label cut.

- Particular blade design, blade base can be change by free, changing blade quickly and conveniently.

- It is easy to change the central clamping device without any tools.

- Oriental rolling label device can be lifting synchronal.

- The separating bottle screw, oriental belt and conveyor are adjusted synchronal, it is easy and quick to do.

- Adopting ANCHUAN servo motor made in JAPAN and sensitive photo electricity, to insure the precision of cutting label.

- Stainless steel electric controller, adopting Mitsubishi PLC made in Japan

- Adopting advanced man-machine automatic controlling technology, main component adopts famous brand.

Shrink wrapping machine

The Shrink Wrapping Machine is designed to efficiently pack and secure bottles, cans, or containers using heat-shrinkable film. It provides strong, durable, and visually appealing packaging — ideal for beverage, water, and food industries. The system includes an automatic film-cutting unit, bottle grouping conveyor, and a high-performance shrink tunnel for smooth and consistent operation. With PLC-based control, stainless steel construction, and energy-efficient heating elements, this machine ensures reliable performance, reduced labor, and optimized production efficiency. We have different kind of shrink wrapping machines for better accuracy according to customer’s requirements.

PE film group packing machine is suitable for wrapping of such products as pop-top, mineral water, bottles, beer, drinks etc. without bottom-tray, working with PE shrink tunnel to pack the goods perfectly, and the completely producing process adopts the Germany advanced technology. In addition, the main parts are imported from international famous companies, Capability stable and using long-time

Linear Type Automatic PE Film Shrink Wrapping Machine is specially designed and manufactured for the high-speed packing requirements of drinks (pure water, beverage, and fruit juice and milk product). It is specially designed for bundle packing of beer, drinks and beverage, fruit juice, bottle water, dairy, condiment and so on with or without bottom support. Unique film layoff mechanism and constant tension film conveyor are adopted, featuring instantaneous film cutting, automatic film connecting and wrapping and higher strength after shrinking packing. Equipped servo motor control system, bottle-feeding, film feeding, film cutting and film wrapping are accurate, synchronous, stable and reliable. The LCD touch-screen has a friendly operation interface, and it is rapid for parameter setting and convenient for human-machine communication, operation and control. Shrink tunnel uses unique air circulation configuration, transfer belt runs smooth, wearable and with longer service life. Use air circulation technology, the shrinkage chamber features unique structure, heat insulation, high precision for temperature control and better packing effects. This machine can increase the printing film packaging system.

This is full automatic series of wrapping machine with servo motor control system. It adopts the photoelectric sensor to detect online, gather signals, which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product. Main character are as below

- Classic shape, beautiful, novel structure, unique, easy operation and maintenance.

- Pneumatic expansion supporting film roll, electronic induction film conveying, stable film feeding, fast and convenient film changing.

- The high polymer step guardrail combined with the retractable bottle separation plate structure makes the products separate smoothly and effectively avoid bottle squeezing

- Shrinkage chamber adopts unique circulating air supply technology to realize multi-directional air volume control technology, with adjustable wind speed and adjustable air outlet position, which greatly improves shrink effect.

- Shrinkage chamber using the newly developed open structure outside to facilitate maintenance; thick insulation layer, energy-saving effect, high temperature control accuracy.

- This model is cost-effective thermal film shrink packaging machine can add hardware and software configuration based on the standard configuration to realize the color film function

Palletization system

The Full Automatic Bottle Robot Palletizer is an advanced end-of-line automation system designed to efficiently stack and organize bottles, cartons, or packs onto pallets with high precision. Using a robotic arm and intelligent vision control, it ensures fast, accurate, and consistent palletizing for various bottle sizes and packaging formats. The system reduces manual labor, increases productivity, and minimizes handling damage. Equipped with PLC and HMI control, adjustable pallet patterns, and safety interlocks, the robot palletizer offers flexibility, reliability, and smooth integration with existing production lines. Its compact design and energy-efficient operation make it ideal for modern beverage, food, and consumer goods industries.

Technical parameters:

- Note: The palletizing speed is related to the size of the pallet and the grouping form of each layer.

- Operation mode: HMI

- Maximum load per layer: 250KG

- Maximum load per pallet: 1600KG

- Maximum stacking height: 1650mm (including tray height)

- Pallet requirements: the best size 1200*1100*150mm;

- Pallet storage: 2 stations, 10-12 pallets

- Motor power supply/power: Three-phase five-wire, AC 380V/50HZ, 15KW

- Control voltage: DC 24V

- Air consumption: 500NL/MIN (air consumption: 4~6MPa) requires filtration, no water, no impurities; air pipe interface size Φ10

- Equipment size: (L)8000MM×(W)4500MM×(H)3000MM

- Equipment weight: 4500KG

- Environmental conditions: best temperature 0-40℃

- Optimum humidity 40-65% RH is the best

De- palletization system for CAN factory

The Depalletizer Machine is designed to efficiently unload and separate aluminum cans, or containers from pallets at the start of the production line. It automates what was once a labor-intensive process, ensuring smooth, fast, and damage-free handling of containers.

Equipped with automatic lifting, layer separation, and conveyor transfer systems, this machine ensures a continuous and stable product flow to the filling line. Built with stainless steel construction and PLC-based control, the depalletizer provides high reliability, easy operation, and low maintenance.Ideal for beverage, water, and food industries, it significantly enhances production efficiency while maintaining product safety and hygiene.

Key Features:

- Automatic pallet lifting and layer separation system

- Compatible with PET bottles, cans, and glass containers

- Smooth and stable container transfer to conveyor line

- PLC and HMI control for easy operation and monitoring

- Adjustable for different pallet sizes and heights

- High-speed operation with minimal product damage

- Durable stainless-steel structure for long service life

- Low maintenance and energy-efficient design

Utilities

The Air Compressor Systems form a vital part of any CSD manufacturing facility, supplying clean, reliable, and consistent compressed air to power various operations such as bottle blowing, filling, labeling, and packaging. These systems combine high-pressure compressors for PET bottle forming and low-pressure compressors for plant-wide pneumatic controls. Each unit is integrated with advanced filtration, air-drying, and storage systems to deliver oil-free, moisture-free air that meets strict food and beverage standards. LP compressors The Low Pressure Air Compressor provides clean, regulated air for pneumatic controls, conveyors, valves, and packaging systems across the CSD production line. It ensures smooth and reliable operation of automated equipment. Usually it creates 10-12bar pressure and flow can be customized as per factory size and production speed.

HP compressors for blow molding machines, especially for PET bottle production, require specialized high-pressure systems to form bottles from heated plastic preforms. The correct choice depends on production volume, bottle size, and required pressure. For high-output applications, we designed a special series of HP Compressors suitable to PET bottle blowing machines, up to 40bar pressure with flow form 4m3/min to 10m3/min as per requirement Advantages Multi-stage compression to achieve the best compression ratio and to maximize energy saving.

- The rotors adopt reasonable compression ratio, to reduce the wear and tear between rotors;

- Skid-mounted with compact design to allow easy installation;

- Easy to use, easy to replace, maintenance without lifting equipment;

A CO₂ storage and supply system for a carbonated soft drink (CSD) factory is a specialized setup designed for the safe storage of liquid carbon dioxide and its reliable delivery as a high-purity gas for the carbonation process. The system ensures consistent quality and uninterrupted supply, both of which are critical for beverage production

- Bulk liquid CO₂ storage tank: This is the central component, a large, insulated cryogenic vessel designed to hold liquid CO₂ at a controlled low temperature and pressure, generally around -18°C and 20 bar (300 psi).

- Vaporizer: Since CO₂ is stored as a liquid, a vaporizer is needed to convert it into a gaseous state for use in the carbonation process. There are several types:

- Ambient vaporizers: Use the surrounding air’s warmth to vaporize the liquid CO₂.

- Heated vaporizers: Use a heat source like electricity, steam, or circulating glycol for vaporization.

- Pressure regulation system: This system includes regulators and safety valves to reduce and control the CO₂ pressure from the storage tank to the safe, usable level required by the carbonation and filling machines

The Chilling System is one of the most critical utilities in a CSD production line, responsible for maintaining the precise temperature required for carbonation and product stability. Proper chilling ensures the maximum CO₂ absorption into the beverage and consistent taste across all batches. The Chilling System provides chilled water (0–4°C) for the CO₂ mixer and filling process in a CSD production line. Cooling the water improves CO₂ absorption, ensuring perfect carbonation and consistent taste.

The system includes a refrigeration chiller, glycol circulation loop, heat exchanger, and temperature control panel. Designed for continuous operation, it maintains stable cooling with minimal energy use.

Key Benefits:

- Ensures stable carbonation and taste quality

- Prevents CO₂ loss and product foaming

- Energy-efficient and low-maintenance operation

- Suitable for continuous 24/7 production

A steam boiler is a crucial piece of equipment used to generate high-quality steam for processes such as sterilization, pasteurization, and cleaning. Since the steam may come into direct contact with food products or containers, a clean and reliable steam source is essential for maintaining product safety and quality.