Cosmetics – Personal care products filling line – Shampoo Filling Line

January 12, 2026

Cosmetics – Personal care products filling line – Hair Oil Filling Line

January 12, 2026Filling Lines – Pet Bottled Sauce Filling Machine

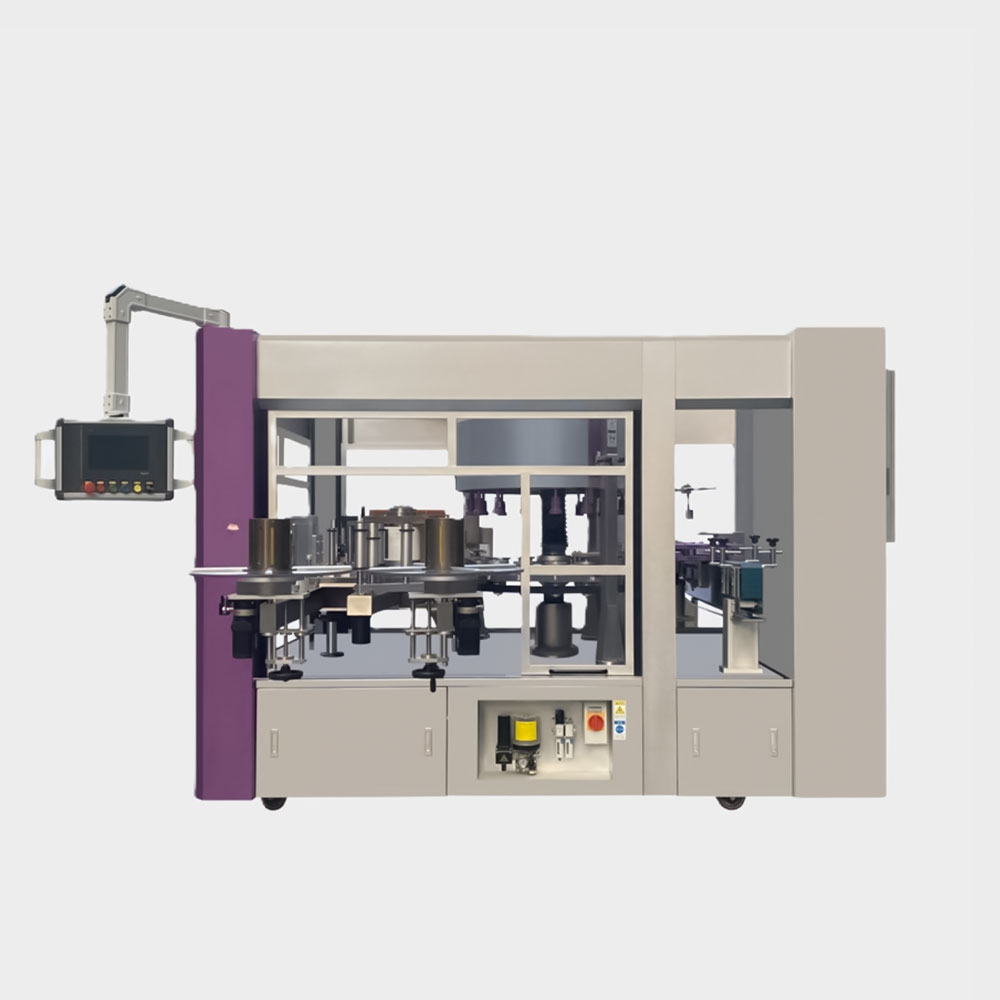

PET Bottled Sauce Filling Machine provides precise and hygienic filling for sauces in PET bottles. Ideal for food production lines requiring automated, high-speed filling with consistent quality.

Pet Bottled Sauce Filling Machine for Food Production

The pet bottled sauce filling machine is designed for industrial food production facilities, providing precise filling for sauces, condiments, and liquid food products into PET bottles. Its high-speed operation ensures consistent fill levels and efficient production for large-scale factories.

Accurate Filling and Hygiene

This machine delivers exact portion control, reducing waste and maintaining product quality. The hygienic stainless steel construction meets food safety standards, ensuring safe filling of sauces and condiments. By automating the process, manufacturers reduce labor costs and maintain consistent output.

Suitable for Various PET Bottles

The filling machine supports multiple bottle sizes and shapes, making it suitable for small 200ml PET bottles up to large 1L or 2L containers. It handles a wide range of sauces, from ketchup and mustard to hot sauces and salad dressings.

Key Features

High-speed PET bottle sauce filling

Precise volumetric filling for consistent quality

Hygienic stainless steel construction

Easy integration with capping, labeling, and packaging lines

User-friendly control system for efficient operation

Industrial Production Design

This machine is engineered for continuous operation in food production factories. It reduces manual labor, improves line efficiency, and ensures consistent quality. By integrating seamlessly with capping and packaging equipment, it forms a complete production line for PET bottled sauces.

Benefits

Fast and precise filling for high-volume production

Maintains product hygiene and quality

Reduces labor costs and human error

Compatible with different bottle sizes and sauce types

Easy integration into complete food production lines

Reviews

There are no reviews yet.