Inspection Machinery – Check Weigher

January 12, 2026

Food Packaging Machine – Quadro Packaging Machine

January 12, 2026Food Packaging Machine – Ketch Up Packaging Machinery

The ketchup packaging machine is designed for food packaging applications requiring hygienic filling and secure sealing of sauces. This machine ensures consistent output and efficient operation for modern food factories.

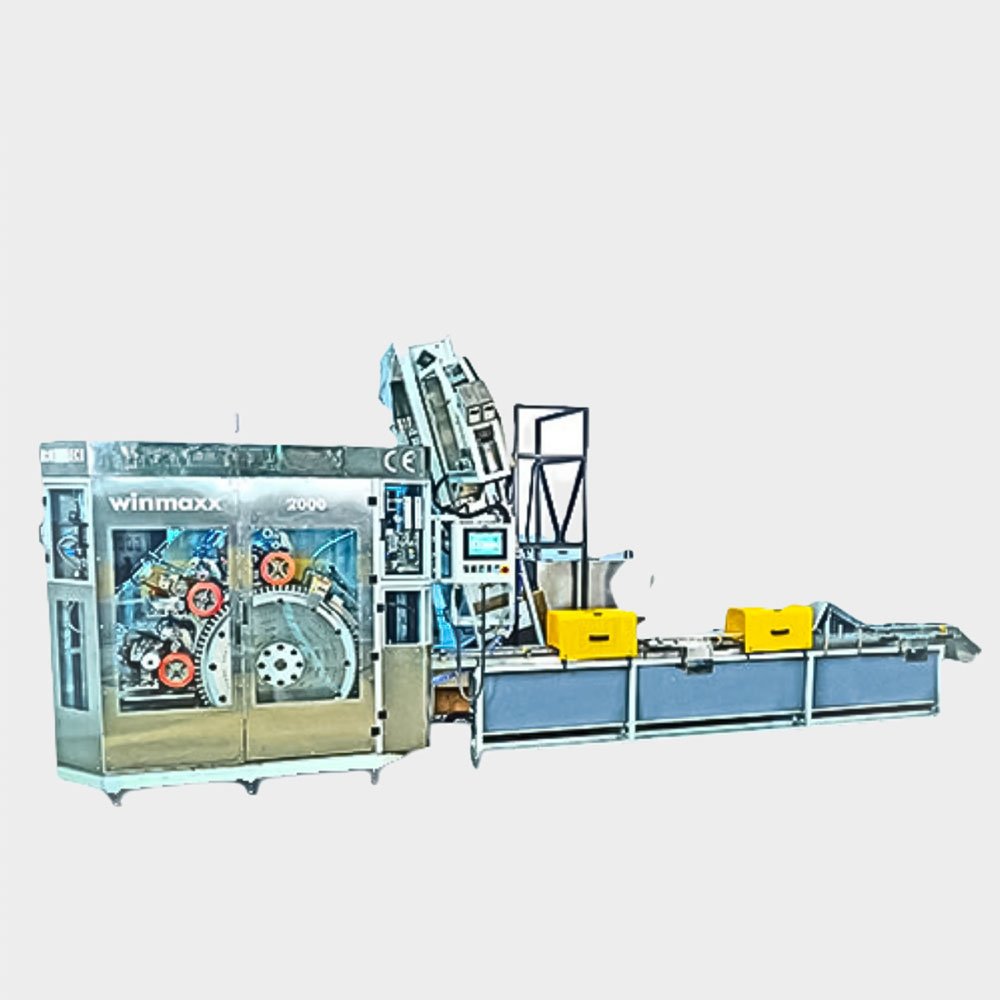

Ketchup Packaging Machine for Food Packaging Applications

The ketchup packaging machine is an advanced food packaging solution developed for accurate, hygienic, and high-efficiency sauce packaging. It is widely used in food processing plants to pack ketchup and other viscous food products into pouches, sachets, or containers with consistent quality.

Efficient Sauce Packaging Performance

This machine delivers precise filling control, which helps maintain uniform weight and reduces product wastage. Moreover, its reliable sealing system ensures leak-proof packaging, protecting ketchup during storage and transportation. As a result, food manufacturers achieve better packaging stability and product safety.

Suitable for Ketchup and Viscous Food Products

In addition to ketchup, this packaging solution supports sauces, pastes, and semi-liquid food products. Therefore, it is suitable for tomato ketchup, chili sauce, mayonnaise, and similar food items. Furthermore, the machine integrates easily with upstream mixing systems and downstream labeling or inspection equipment.

Key Features of Ketchup Packaging Machinery

Accurate volumetric or piston filling system

Hygienic food-grade stainless steel structure

Stable pouch or sachet sealing

Easy cleaning and maintenance

Compatible with food packaging production lines

Designed for Industrial Food Factories

The ketchup packaging machine is engineered for continuous operation in industrial food environments. Additionally, it can be combined with check weighers, metal detectors, and labeling machines to create a complete food packaging line. This integration improves production efficiency and minimizes downtime.

Why Choose This Food Packaging Solution

Compared to conventional packaging equipment, this machine offers better control over filling accuracy and sealing consistency. Consequently, food manufacturers benefit from improved productivity, reduced waste, and reliable packaging quality.

Reviews

There are no reviews yet.