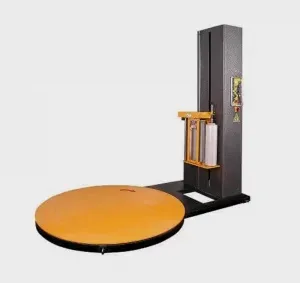

Packaging machines are essential for efficient and hygienic packaging in beverage, food, and cosmetic industries. F&N International offers advanced automatic packaging equipment, shrink wrapping machines, pillow packing systems, and DoyPack packaging lines for high-speed, precise, and reliable operations.