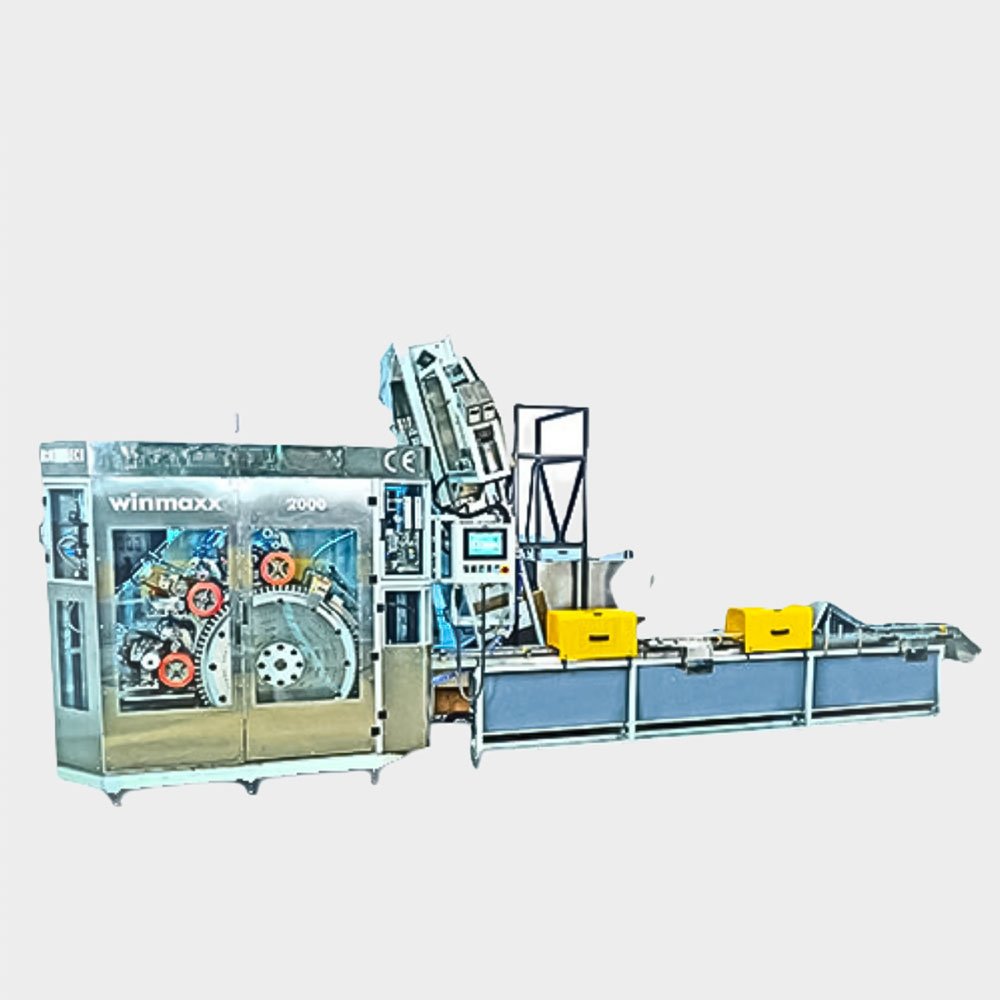

Food processing machines are essential for efficient and high-quality production in bakery, confectionery, and general food industries. F&N International provides advanced automatic food processing equipment, including filling, packaging, and inspection machines designed for hygienic, precise, and high-speed operations.

1

2