Food PE Film Wrapping Machine - Automatic Linear Type Film Shrink Wrapping Machine With Half Tray in Pakistan, UAE, Qatar, Oman, Saudi Arabia and Morocco

Product Features

- The optimization of equipment with straight line shape design, beautiful shape, covers an area of reduction.

- Equipment subject use high quality carbon steel material gives priority to made, in part by South Korea’s posco stainless steel.

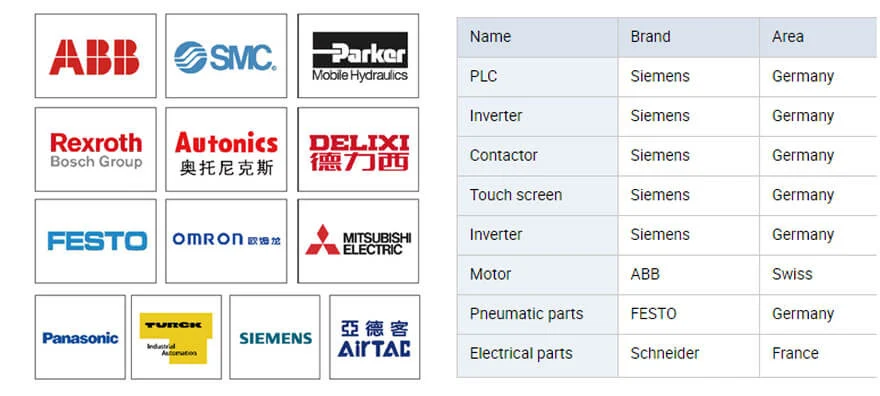

- Electrical system adopts imported PLC programmable control, the transmission process uses the import frequency converter, machine operation process using imported touch screen control, make equipment into action control sitzerlan intelligent state, the movements are monitored, all kinds of alarm, PC state are on glass display, make the equipment operation more safe, reliable, and can a single step action, debug and maintenance. Equipment has automatic alarm device set and special protection function, further improve equipment safety and reliability.

- Pneumatic components choose Taiwan brand.

- Using manipulator to be automatic and cardboard way.

- The main electrical components are imported or domestic quality brand.

- Traction film feeding: film feeding speed adjust themselves.

- Heat shrinker: the sino-us cooperation with our production fluoro conveying, corrosion resistance, smooth conveying, speed can be adjusted, PLD control, temperature can be adjusted, the unique hot air processing, make the packaging shrinkage beautiful.

Frequenty Asked Questions (FAQs):

Few of the most frequently asked questions about the product are answered here. If have any specific question, please feel free to contact us.

Q. How about spare parts availibility?

A. We will send one year enough easy broken spare parts together with the machines, shipping together. During the warranty time, we will supply the spare parts with our cost including the delivery fees.

Q. How much time is required for installation?

A. According to your machines order, we shall send qualified engineers to your plant, it may take about 10 days to 25 days, depending upon your order and any customization.

Q. Who will be responsible for the installation of machines?

A. Our qualified engineers will be responsible for installation of the machines.

Q. Will you train our staff to operate the machines?

A. Yes, our qualified engineers will train your staff to operation the machines.

Q. How to install my machine when it arrives at my factory? How much is the cost of installation?

A. We shall send our engineers to your factory for installation of machines and train your staff how to operate. Customers pay for two-way air tickets, accommodation and USD80 per person per day as daily allowance.

Q. When can I get my machine after the payment?

A. Normally production time is around 30-60days, the exact delivery date will depend upon your order, the machine type and any customization requirements. The shipping time is based on your destination port.

Q. How about the spare parts availability?

A. We will send one year enough easy broken spare parts together with the machines, shipping together. During the warranty time, we will supply the spare parts with our cost including the delivery fees.

Technical Specifications :

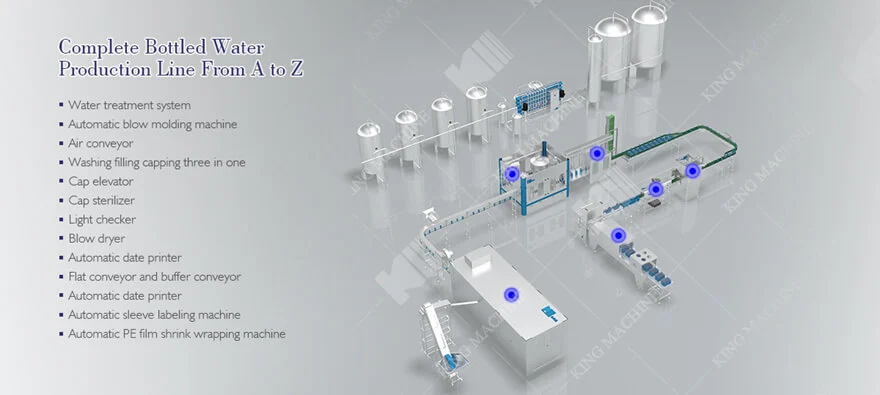

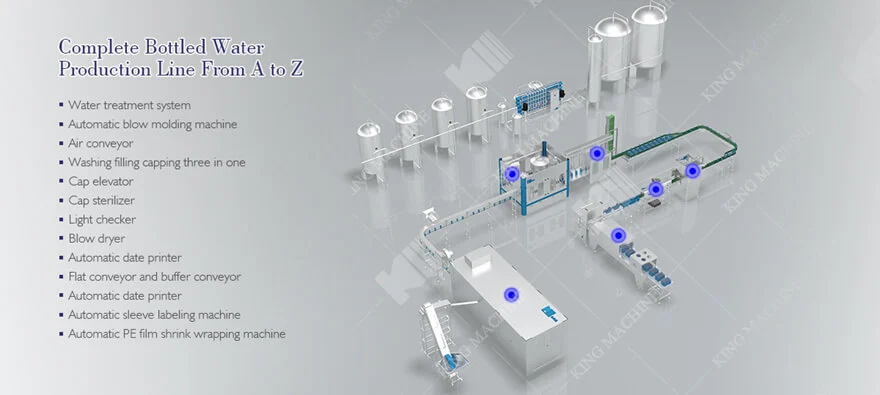

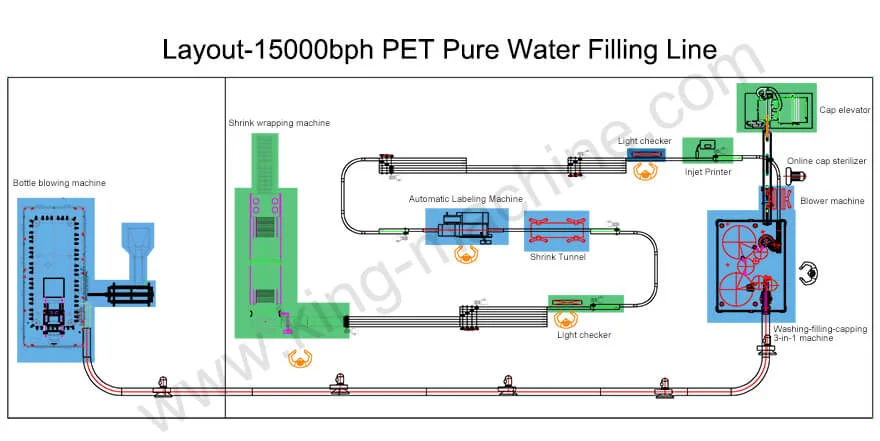

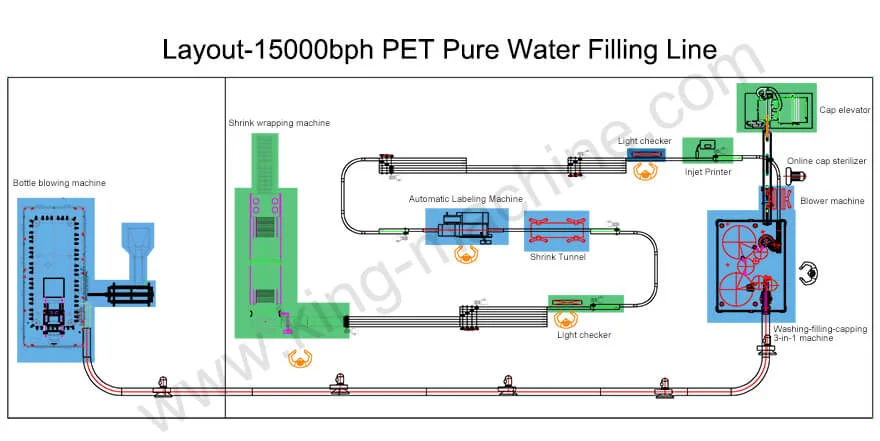

Flow chart: (Pure Water Filling Machine)::

Our Partners

Want to contact us?

If you’ve got questions or ideas you would like to share, send a message. For anything more specific, please use one of the addresses listed below.

Get Competitive Quote

Please share your contact information, so that we can get back to you with our best quote.