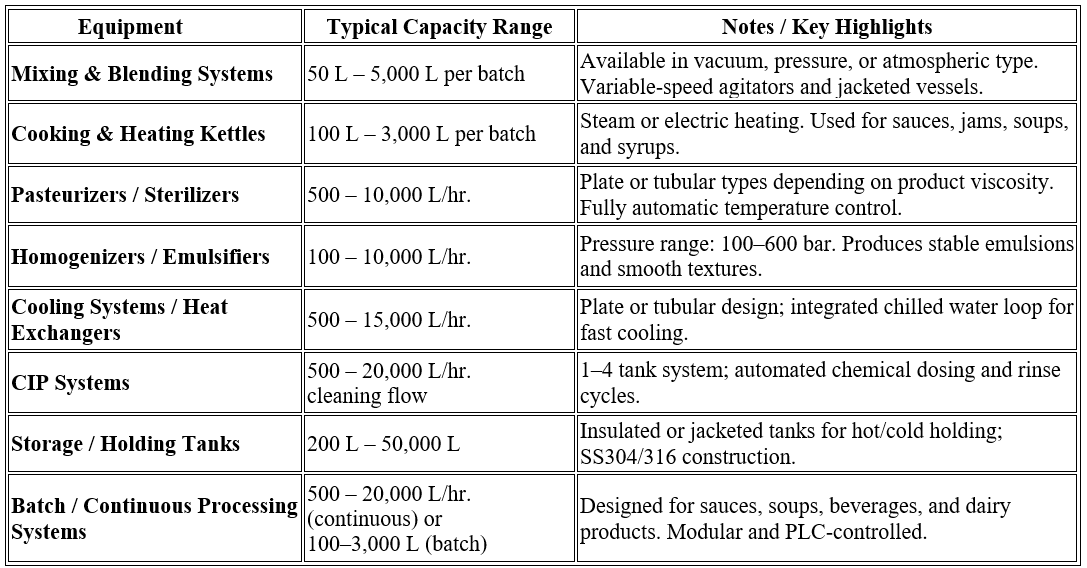

Mixing & Blending Systems (sauces, creams, dressings)

These systems combine raw ingredients—liquid, semi-liquid, powders, emulsions—into uniform mixed batches for sauces, creams, dressings and more. Blending aims for gentle combination of components; mixing (often with high shear) aims for a homogenous, consistent product.

Key Features & Highlights:

Blending or mixing mode selectable (ribbon, paddle, high-shear or vacuum) depending on product viscosity, Variable speed agitators and impellers to handle low-viscosity to high‐viscosity materials, Built-in heating/cooling jackets for control of batch temperature, Vacuum or inert gas options for deaeration during mixing (for creams, emulsions), Sanitary design (SS304/316, polished finish) to meet hygiene standards.

Easy cleaning access, often CIP compatible, High capacity scale: suitable for small batches up to large industrial volumes, Accurate ingredient dosing and mixing repeatability for consistent product quality.

Cooking & Heating Kettles (jam, ketchup, soups)

These vessels are used to cook, heat or pasteurize sauces, jams, soups and semi-solid foods. They allow precise control of temperature, agitation and residence for quality and safety.

Key Features & Highlights:

Jacketed or direct steam heating for rapid temperature rise and consistent cooking, Stirring mechanisms (agitators, scrapers) to prevent burning, handle viscous products, Insulated construction to conserve energy and maintain temperature, Temperature sensors, PID / PLC control for automated, accurate heating, Suitable for batch processing (kettle) or continuous cooking as required, Capacity and design customizable for product type (low viscosity, high pulp, chunky sauces), Safety features: pressure relief, explosion-proof (if steam) and hygienic construction.

Pasteurizers & Sterilizers (liquid and semi-solid foods)

This equipment ensures food safety and shelf-life by heating products to required temperatures for a specified time, then cooling them. For liquids and semi‐solids, pasteurization or sterilization are essential.

Key Features & Highlights:

Plate type for clear, low viscosity products; tubular type for thicker or pulpy products.

Regenerative heat exchange to recover energy and improve efficiency.

Holding tubes or sections to ensure correct residence time.

Automated temperature, flow and pressure control via PLC.

CIP-compatible design for hygiene.

Construction: SS316L, sanitary welds, minimal dead zones, Accurate temperature control (typically ±0.5 °C) for consistent results, Suitable for juices, sauces, dairy, soups and more.

Homogenizers & Emulsifiers (smooth texture and stability)

Homogenizers and emulsifiers are used to create stable emulsions (oil-in-water mixtures, creams) and to reduce particle size so that the product remains uniform and stable over time.

Key Features & Highlights:

High shear mixing elements that produce fine droplet sizes for stable emulsions, Capable of handling high-viscosity products (creams, thick sauces) or products needing fine dispersion (dressings, emulsified sauces), Variable pressure/temperature control for customization of product texture, Sanitary design, easy cleaning, often integrated into mixing tanks, Enhances product stability, prevent separation, improves mouth feel and quality.

Cooling Systems & Heat Exchangers

Cooling systems and heat exchangers remove heat after cooking or pasteurization and bring products to the correct temperature for filling or storage, preserving product integrity.

Key Features & Highlights:

Plate or tubular heat exchangers for efficient heat transfer, Closed loop chilled water or glycol system to achieve target temperature, Integrated controls for temperature, flow rate and pressure to maintain optimal conditions,Hygienic, stainless‐steel construction; minimal dead zones for cleaning,Can be used for cooling sauces, creams, beverages or pre-chilled holding tanks, Assists in process continuity by reducing bottlenecks due to long cooling times.

CIP (Clean-in-Place) Systems for hygiene maintenance

CIP systems automate the cleaning of tanks, pipelines, heat exchangers and equipment without disassembly. They ensure hygiene, reduce downtime and maintain high production efficiency.

Key Features & Highlights:

Automated control of cleaning cycles: pre-rinse, chemical wash (alkali/acid), final rinse, PLC/HMI touch screen interface to set cleaning recipes, monitor parameter(flow, temp, pH), Multi-circuit design allows cleaning of multiple lines simultaneously, reducing downtime, Sanitary construction: SS304/316, sealed valves and pumps, minimal operator exposure, Built-in monitoring and logging for compliance (GMP, HACCP), Utility savings: optimized water, chemical and energy usage.

Storage & Holding Tanks (insulated, jacketed)

These tanks store raw materials, intermediate blends and finished products. They may include heating/cooling jackets, insulation, sampling ports and transfer pumps.

Key Features & Highlights:

Capacity sizes customized to batch size and processing volume, Jacketed construction with heating or cooling circulation (steam, hot water, glycol) for temperature control, Insulated body to maintain temperature and reduce energy loss, Sanitary access: manhole, CIP spray balls, sampling ports and level sensors, Food-grade stainless steel (SS304/316) with polished interior finish for hygiene, Integrated instrumentation: level sensors, temperature, pressure, PLC interface, Suitable for storage of water, syrups, blends, final product.

Batch and Continuous Processing Systems

These refer to entire systems that either process food in defined batches (batch processing) or continuously feed product through a processing line (continuous processing). The choice depends on product type, volume, flexibility and footprint.

Key Features & Highlights:

Batch systems: high flexibility, easy changeover for different products, suitable for small/medium production, Continuous systems: high throughput, minimal manual intervention, optimized for large scale production, Fully automated controls: recipe management, PLC, HMI interface, integrated data logging, Modular design enabling scalability and quicker installation, Efficient resource utilization – energy, water, labour; reduced wastage, Integration with upstream & downstream equipment (mixers, cookers, fillers, conveyors).