Automatic Bleach Liquid Filling Machine by F&N International in Pakistan, UAE, Qatar, Oman, Saudi Arabia and Morocco is a fast and efficient machine that can process strong acids, bases, bleach and corrosive liquids.

Product Features

- Host adopts advanced PLC automatic control technology, the key electrical components from famous companies such as Japan’s Mitsubishi, France Schneider, and OMRON.

- Made of stainless steel and advanced aluminum alloys and complies with ISPE regulations for GMP – Good Manufacturing Practice.

- Adoptive PLC control system to make the whole machine run stably and at high speed

- Adoptive touch screen control which makes it very easy to operate.

- 24/7 support from F&N International qualified and trained engineers.

- Please refer duly executed quote for the final specification. These features are generic in nature.

Some of the well know vendors providing Automatic Bleach Liquid Filling Machine are:

Frequenty Asked Questions (FAQs):

Few of the most frequently asked questions about the product are answered here. If have any specific question, please feel free to contact us.

Q. How about spare parts availibility?

A. We will send one year enough easy broken spare parts together with the machines, shipping together. During the warranty time, we will supply the spare parts with our cost including the delivery fees.

Q. How much time is required for installation?

A. According to your machines order, we shall send qualified engineers to your plant, it may take about 10 days to 25 days, depending upon your order and any customization.

Q. Who will be responsible for the installation of machines?

A. Our qualified engineers will be responsible for installation of the machines.

Q. Will you train our staff to operate the machines?

A. Yes, our qualified engineers will train your staff to operation the machines.

Q. How to install my machine when it arrives at my factory? How much is the cost of installation?

A. We shall send our engineers to your factory for installation of machines and train your staff how to operate. Customers pay for two-way air tickets, accommodation and USD80 per person per day as daily allowance.

Q. When can I get my machine after the payment?

A. Normally production time is around 30-60days, the exact delivery date will depend upon your order, the machine type and any customization requirements. The shipping time is based on your destination port.

Q. How about the spare parts availability?

A. We will send one year enough easy broken spare parts together with the machines, shipping together. During the warranty time, we will supply the spare parts with our cost including the delivery fees.

Technical Specifications :

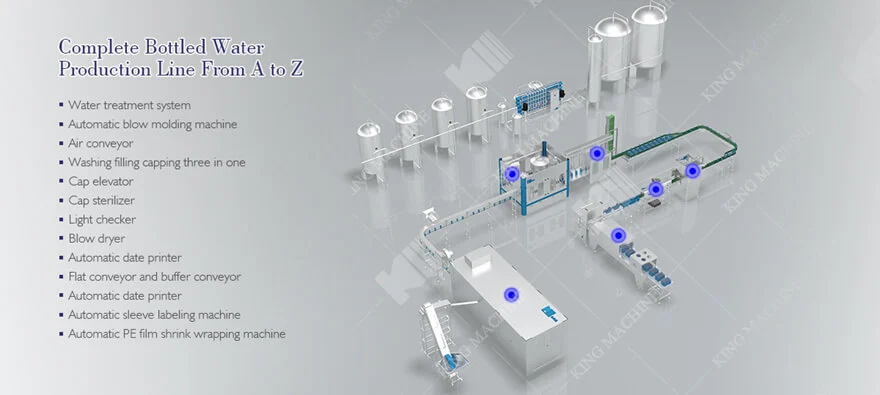

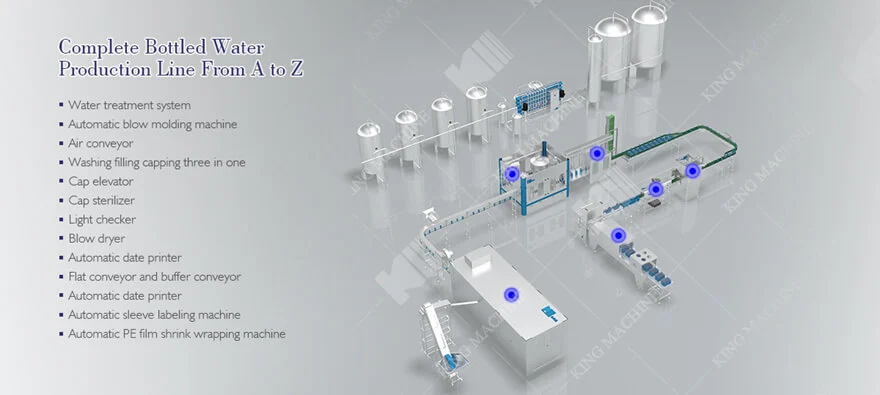

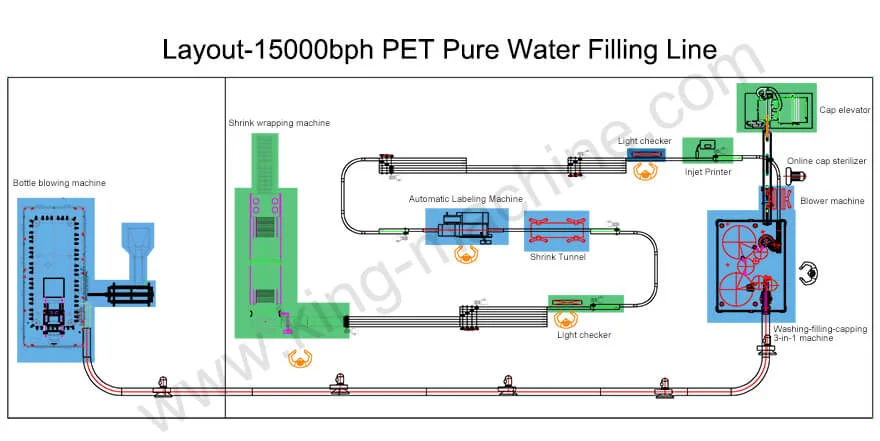

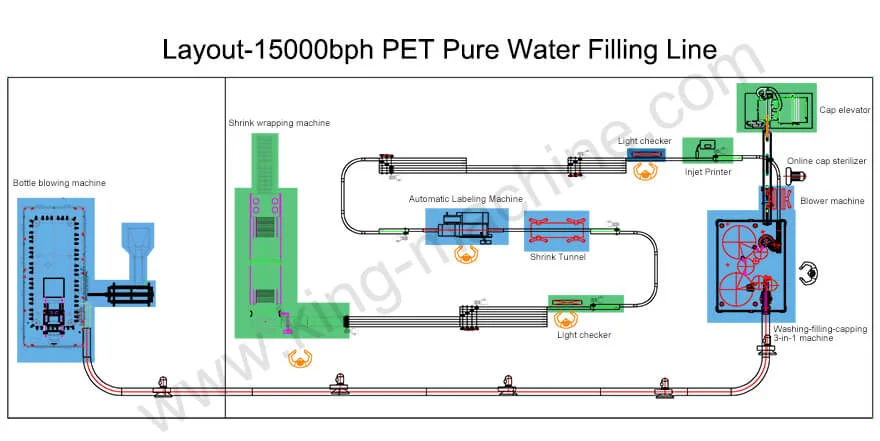

Flow chart: (Pure Water Filling Machine)::

Our Partners

Want to contact us?

If you’ve got questions or ideas you would like to share, send a message. For anything more specific, please use one of the addresses listed below.

Get Competitive Quote

Please share your contact information, so that we can get back to you with our best quote.