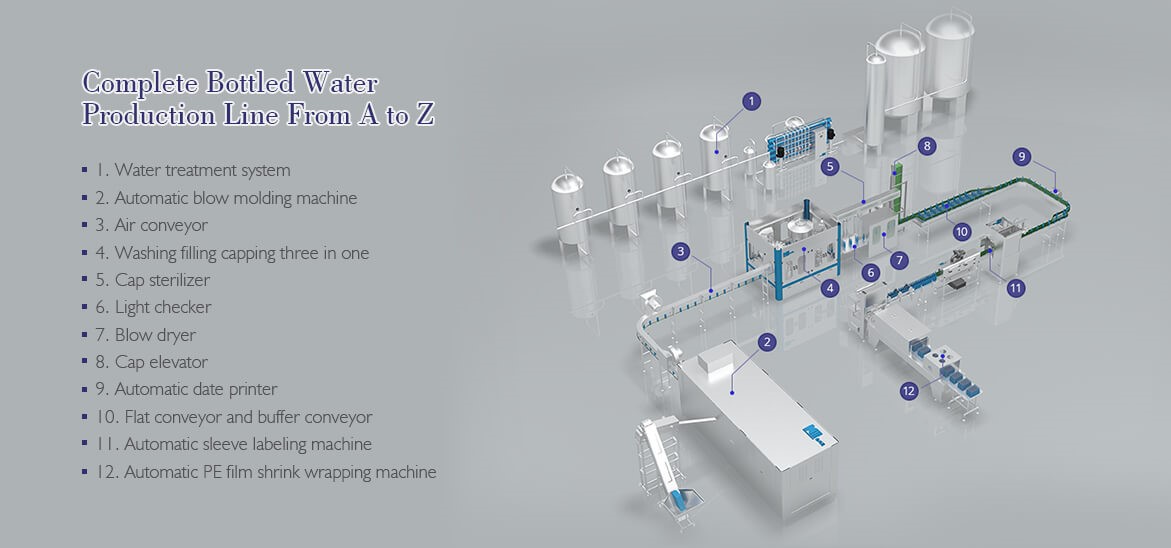

Pure Water Production Line

Our Water PET Bottle Filling Line is designed to deliver crystal-clear quality and efficient production for still and mineral water packaging. From bottle blowing to filling, capping, labeling, and packaging, the entire system operates with precision and hygiene at every stage. Built with advanced automation and stainless-steel construction, this line ensures consistent performance, reduced downtime, and long-term reliability — meeting international food and beverage safety standards.

Ideal for small to large-scale water bottling plants, our turnkey solutions can be customized for multiple bottle sizes and capacities ranging from 200ml to 2.0L

Turnkey Pure Water Production Plant Solutions

Our turnkey pure water processing plant Pakistan solutions cover every step of water production and packaging. As a trusted industrial machinery supplier in Pakistan, F&N International provides machinery for water purification, filtration, bottling, and packaging. We handle the entire setup as a turnkey plant solution provider, ensuring your production line is fully operational with minimal downtime.

we help businesses design efficient layouts, meet industry standards, and optimize operational costs. Whether it’s a Beverage production plant or a Can selling equipment line, our solutions are tailored for your needs.

Water treatment system

- Features: Treatment capacity 0.5-50T/Hr. with customized deign option asper requirement.

- Remove 99.9% ions, adopted Hydecnme (American brand) membrane, body material SS304 & SS316. Fully automatic control and water testing system

- Equipment including are pre filtration, hollow fiber, RO, UV sterilizer, precision filter, ozone generator, water tank etc.

Capacity range- 3T/Hr – 70T/Hr

Material – all tanks & pipes SS304

Automation- HMI controlled recipe system (optional)

- Removes up to 90–99% of total dissolved solids (TDS), salts, and other impurities.

- Optimized for 50–75% recovery, depending on feed water quality and system design.

- Can be design in single or multiple membrane housings (pressure vessels) to match the plant’s capacity requirements.

- Plug-and-play design allows quick membrane replacement and minimal downtime.

- The products adopt a high-intensity, long-lived UV germicidal lamp to achieves up to 99.99% microbial kill rate, ensuring water safety at the final stage.

- Ozone (O₃) effectively destroys bacteria, viruses, mold, and organic contaminants improving clarity and taste.

- Decomposes naturally into oxygen after treatment — no harmful byproducts.

- Designed to store RO-treated or sterilized water before distribution or filling, ensuring maintained purity and quality.

- Made from food-grade stainless steel (SS304/SS316) to prevent contamination and corrosion. Made from food-grade stainless steel (SS304/SS316) to prevent contamination and corrosion.

Processing System

The Processing System is the heart of the CSD production line — where raw materials such as treated water, sugar, flavors, and carbon dioxide transformed into a finished beverage ready for filling. This stage determines the taste, consistency, carbonation quality, and shelf life of the final drink, making it one of the most critical areas of beverage manufacturing.

Our processing system integrates several interconnected units working in harmony to ensure precise mixing, accurate carbonation, and hygienic handling of the beverage. All equipment (like tanks, filters, piping, valves, pumps, heat exchangers, etc.) are food grade made of SS304/SS316 and process flow is design as per GMP standards with advanced automation.

CIP system (optional from water line)

Automatic CIP system is specially designed for the clean up of beverage production line and filling equipment, with three cleaning sections of Acid, Alkali and Hot water and temperature can be set up as per requirement.

Function: The CIP SYSTEM can cleaning equipment of blending system automatically, from start until to the end of cleaning Work, all jobs are done by the control system automatic performance which function had been set in advance, the operator only Makes the switching operation, all blending system equipment will be cleaned fast and simply.

Features: SUS304, split type, double circuit design, four tank system, tube heating, automatic control, acid, lye, hot water tank are thermal insulation tank, single-layer clear water tank, inner cylinder 3mm thick, outer 2mm thick, insulation tank using PU polyurethane foam, thickness of 60mm. The top of the acid and lye tank is offset and stirred at 36rpm.

In full automatic system can control product in and out, heating temperature and discharge temperature, automatic control and compensation of acid and alkali concentration. Automatic adjustment of cleaning flow, automatic alarm of cleaning equipment failure, automatic control of tank liquid level, automatic switching of CIP process

PET Blowing section

Our PET Blowing Machine is designed for efficient and precise production of PET bottles used in beverages, water, and edible oil industries. With advanced heating and stretch-blow molding technology, it ensures consistent bottle quality, high output, and energy-efficient operation. Available in both linear and rotary models, it supports a wide range of bottle sizes and shapes with rapid mold changeover and stable performance.

Water Filling & Packaging Machines

We offer a wide range of water bottle packaging machines, liquid filling machine Pakistan, automatic pouch filling machine Pakistan, and bottle filling machine solutions. Our packaging machinery supplier Pakistan services include automatic packaging machines, flexible packaging machines Pakistan, and labeling machines for bottles, ensuring safe and hygienic water packaging.

Our B2B packaging solutions Pakistan allow your production line to meet both local and international standards for bottled water.

ombi-block filling machine, also called blowing filling capping combi-block. Specially designed for précised/accurate product at high-speed like12000bph-54000bph.

The main advantages of the combi-block are high efficiency with better quality product, large output, less space, less operator, saving resources and costs with higher earning. Attractive Features are below.

Mechanical or volumetric electronic filling valve Tubular type filling bowl no dead angle, easy to clean Automatic CIP, easy for operation and maintenance Raise filling temperature above 12~15°C for energy saving Volumetric valve leads to high filling precision, 5~6 times higher than mechanical valve Volumetric valve filling can realize fast changeover, no vent tubesAir dryer

This machine installed after the filling machine/warming tunnel, In order to dry the bottles body from outside. This machine is used to removing the water outside the bottle surface;

the major component of the machine is air blower. With the help of high-speed motor, it through the air on bottles and remove water drops from it. The blowing capacity can be adjust through the button.

Labeling system

The OPP Labeling Machine is designed for high-speed and precise labeling of PET bottles using Oriented Polypropylene (OPP) labels. It ensures smooth and accurate label application with minimal material waste, making it ideal for beverage, water, and food production lines. Featuring automatic label positioning, hot-melt glue system, and PLC control, the machine delivers consistent performance even at high speeds. Its stainless-steel structure, energy-efficient design, and easy maintenance make it a reliable choice for modern packaging operations.</p>

Features:

- Adopting four pole support method

- Adopting the latest straight in and straight out adhesive coating method.

- Adopting the latest adjustable collision block structure.

- Adopting multiple servo motors for accurate motion of mechanical parts

- Adopting an independent module approach for heating system.

- Adopting the German imported Leimer E+L label correction system.

- The machine is equipped with dual material tray with automatic label connection system.

Shrink wrapping machine

The Shrink Wrapping Machine is designed to efficiently pack and secure bottles, cans, or containers using heat-shrinkable film. It provides strong, durable, and visually appealing packaging — ideal for beverage, water, and food industries. The system includes an automatic film-cutting unit, bottle grouping conveyor, and a high-performance shrink tunnel for smooth and consistent operation. With PLC-based control, stainless steel construction, and energy-efficient heating elements, this machine ensures reliable performance, reduced labor, and optimized production efficiency. We have different kind of shrink wrapping machines for better accuracy according to customer’s requirements.

Linear Type Automatic PE Film Shrink Wrapping Machine is specially designed and manufactured for the high-speed packing requirements of drinks (pure water, beverage, and fruit juice and milk product). It is specially designed for bundle packing of beer, drinks and beverage, fruit juice, bottle water, dairy, condiment and so on with or without bottom support. Unique film layoff mechanism and constant tension film conveyor are adopted, featuring instantaneous film cutting, automatic film connecting and wrapping and higher strength after shrinking packing. Equipped servo motor control system, bottle-feeding, film feeding, film cutting and film wrapping are accurate, synchronous, stable and reliable. The LCD touch-screen has a friendly operation interface, and it is rapid for parameter setting and convenient for human-machine communication, operation and control. Shrink tunnel uses unique air circulation configuration, transfer belt runs smooth, wearable and with longer service life. Use air circulation technology, the shrinkage chamber features unique structure, heat insulation, high precision for temperature control and better packing effects. This machine can increase the printing film packaging system.